Yes, the density is off in this case, there is also loads of damping. This is just a trick to reach a quasi-steady solution quicker and without oscillations. I am not interested in the dynamics.

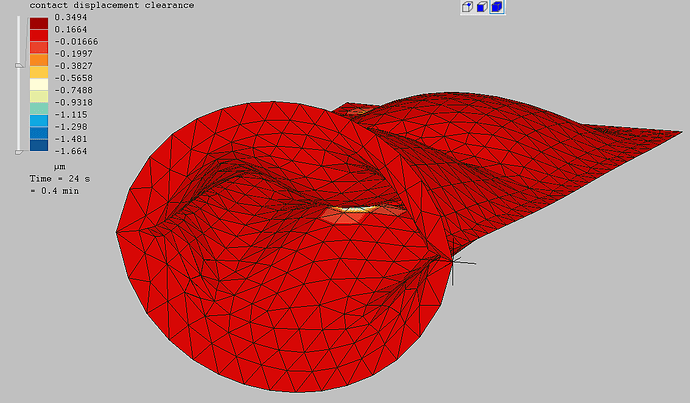

I have a better insight of your model. I solve it with nonlinear quasistatic to see what was going on.

Unilateral contact is a nonlinear behaviour.----> Nonlinear Analisys

Seems like the lip is buckling. I had to add some additional BC in the y direction.

Meantime I Have been able to solve with a unique step playing with the Amplitudes.

MODEL CHANGE card, I will have too look further.

Yes, the file on GitHub only has z-displacements BC. I can provide the y if you want, but it seems you have solved it.

The first step can indeed be done through a quasistatic step. That might be a good alternative to my dynamic step to get the geometry into the deformed configuration.

@Disla, well, actually, I solved the issue with your approach.

I made the first quasistatic step (with contact) that forms the geometry. Followed by another quasistatic step, that continues to “inflate” the model and impose contact. It works, and runs much better than the dynamic sim.

*INCLUDE, INPUT=geom.inp

*INCLUDE, INPUT=EDGE.nam

*AMPLITUDE, NAME=A1

0.0,0.0,1.0,1.0,100.0,1.0

*AMPLITUDE, NAME=A2

0.0,0.0,1.0,1.0,2.0,1.0,102,10.0

*AMPLITUDE, NAME=A3

0.0,0.0,1.0,1.0,2.0,1.0,102,44.2

*AMPLITUDE, NAME=A5

0.0,1.0,100.0,10.0

*AMPLITUDE, NAME=A6

0.0,1.0,100.0,40.0

*BOUNDARY

EDGE, 1, 1, 0.000000

*INCLUDE, INPUT=BCs_EDGE_TOP.nam

*INCLUDE, INPUT=BCs_EDGE_BOTTOM.nam

** Material properties

*MATERIAL,NAME=MEMBRANE

*ELASTIC

300000.000000, 0.330000

*DENSITY

0.8

*DAMPING, ALPHA=100.00, BETA=0.00

*SHELL SECTION, MATERIAL=MEMBRANE, ELSET=PLATE

0.0001

** contact conditions

*SURFACE INTERACTION,NAME=IN1

*SURFACE BEHAVIOR,PRESSURE-OVERCLOSURE=LINEAR

30000.0, 3000, 1e-3

** last two are irrelevant for face-to-face contact

*FRICTION

0.3, 3000.0

** first one is dimensionless friction coefficient 0.1 < μ < 0.5,

** second one is shear strength, sould be ~K/10

*SURFACE,NAME=dep1,TYPE=ELEMENT

SRF_2,SNEG

*SURFACE,NAME=ind1,TYPE=ELEMENT

SRF_7,SPOS

*SURFACE,NAME=dep2,TYPE=ELEMENT

SRF_3,SNEG

*SURFACE,NAME=ind2,TYPE=ELEMENT

SRF_8,SPOS

*CONTACT PAIR,INTERACTION=IN1,TYPE=SURFACE TO SURFACE

dep1,ind1

*CONTACT PAIR,INTERACTION=IN1,TYPE=SURFACE TO SURFACE

dep2,ind2

** STEP the model

*STEP, NLGEOM, INC=1000000

*STATIC

0.1, 1.0

*DLOAD, AMPLITUDE=A1

SRF_1, P1, 0.3800

SRF_6, P1, -0.3800

*DLOAD, AMPLITUDE=A3

SRF_2, P1, -0.1000

SRF_3, P1, -0.1000

*DLOAD, AMPLITUDE=A2

SRF_4, P1, 0.4800

SRF_5, P1, 0.4800

*DLOAD, AMPLITUDE=A3

SRF_7, P1, 0.1000

SRF_8, P1, 0.1000

*DLOAD, AMPLITUDE=A2

SRF_9, P1, -0.4800

SRF_10, P1, -0.4800

*NODE FILE,OUTPUT=2D

U,

*EL FILE

E, ME, S, ENER

*END STEP

** second step to test the contact

*STEP, NLGEOM, INC=1000000

*STATIC

0.01, 20.0

*DLOAD

SRF_1, P1, 0.3800

SRF_6, P1, -0.3800

*DLOAD, AMPLITUDE=A6

SRF_2, P1, -0.1000

SRF_3, P1, -0.1000

*DLOAD, AMPLITUDE=A5

SRF_4, P1, 0.4800

SRF_5, P1, 0.4800

*DLOAD, AMPLITUDE=A6

SRF_7, P1, 0.1000

SRF_8, P1, 0.1000

*DLOAD, AMPLITUDE=A5

SRF_9, P1, -0.4800

SRF_10, P1, -0.4800

*NODE FILE,OUTPUT=2D

U,

*EL FILE

E, ME, S, ENER

*END STEP

I will try to adapt that to my actual model, but I think it’s all sorted.

Thanks a lot to you all, @Calc_em @Disla @jbr, for the help.

Best,

Marin