Hello everyone,

I am trying to simulate the interaction of a beam under bending while the whole body (every node) is subjected to a (unidirectional/orthotropic) thermal expansion:

A cantilever with a fixed support on the left side is subjected to a force perpendicular to the beam axis at the free end on the right side. The maximum displacement occurs at the free end.

Additionally, a thermal expansion is applied, which makes the beam longer (only in longitudinal direction so the cross-section remains constant) and therefore the deflection should be higher compared to a purely mechanical simulation.

The purely mechanical simulation without thermal expansion works fine and the maximum displacement corresponds to the analytical solution

wmax = 1/3*F*L³/(EI) = 1/3*(1050000N)*(2.00m)³/(210000e6N/m²*1/7500 m⁴)

= 0.1 m

with a rectangular cross-section b/h = 0.2/0.2 m

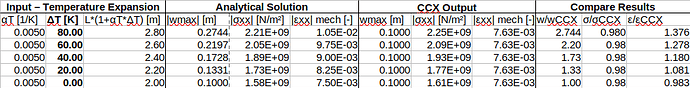

If I apply a thermal expansion and the length of the beam becomes Lth = 2.8m, the maximum deflection should be

wmax = 0.1m*(2.8m)³/(2.0m)³

= 0.2744 m

but I still receive the same deflection of 0.1m.

I tried different simulation types (*Static, *Uncoupled Temperature-Displacement, *Coupled Temperature-Displacement) and different ways to increase the temperature (*Initial Conditions=Temperature with *Temperature or *Boundary DOF 11). Sometimes I received error messages, that either the initial temperature or the final temperature in a node is not specified.

Here is one input file of a working simulation, even though it took 3 hours to finish.

************************** Mesh ***************************

**

*INCLUDE, INPUT= ./all.msh

**

**

****************** Node and Element Sets ******************

**

**In ./all.msh

**

**

************************* Materials ************************

**

*Material, Name=DummyMat

*Elastic

210000e6, 0.1

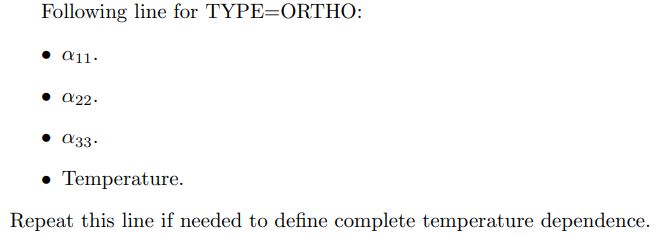

*Expansion, Zero=273.0,TYPE=ORTHO

0.005,0.0,0.0

*DENSITY

7850.0

*SPECIFIC HEAT

500.0

**

**

************************* Sections *************************

**

*Solid section, Elset=Eall, Material=DummyMat

**

**

*************************** Step ***************************

**

**Time Points

*TIME POINTS,NAME=T1,GENERATE

0.0,10.0,1.0

**

**

**

** Supports

*Boundary,fixed

Nsurfleft,1,3

**

** Initial Temperature

*INITIAL CONDITIONS,TYPE=TEMPERATURE

Nall,273.

**

**

*Step,NLGEOM=YES,INC=10000000000

*COUPLED TEMPERATURE-DISPLACEMENT

1.0e-2,10.0

**

**

*Cload

Nsurfright,3,-16150

**

**

**Temperature

**Nall,353.0

**

*BOUNDARY

Nall,11,11,353.

**

** Output .frd

*Node file,TIMEPOINTS=T1

RF, U, NT

*El file,TIMEPOINTS=T1

S, E, NOE, ENER

**

** Outputs .dat

*NODE PRINT, NSET=Nsurfright, TOTALS=ONLY,TIMEPOINTS=T1

RF

*NODE PRINT,NSET=Nall,TIMEPOINTS=T1

U

**

*End step

**

I used C3D20R elements. The cload is applied to 65 nodes at the free end.

Any idea how I can adjust the simulation for increased deflection due to thermal expansion?

Thanks,

Felix